As much as 65% of all UPS back-up system power failures are battery related. That’s a staggering number, but is easier to understand when you consider all the potential issues that can affect UPS batteries. Power anomalies, overheating, improper charging or low electrolyte levels for certain types of batteries can all cause serious issues for the UPS.

Since batteries are the heart of a UPS system, proactive testing and maintenance are key to ensuring a long life cycle. However, batteries can fail quickly, sometimes in as little as a few weeks, and failure can occur at any time during a battery’s life. For example, changes in environment (e.g., temperature) can accelerate battery failures. Thus, while proactively testing UPS batteries is important, some customers may benefit from battery monitoring as an effective way to view and compare your battery health trends over time. Think of it as comparing a snapshot photo (routine testing), to a continuous video (constant monitoring).

Because of the critical nature of the UPS, frequent battery failure or inconsistent battery performance for most applications cannot be tolerated and for many of our clients, they need a way to monitor the life and health of their batteries on a constant basis.

There are two main methods that are available to proactively test and monitor your battery health.

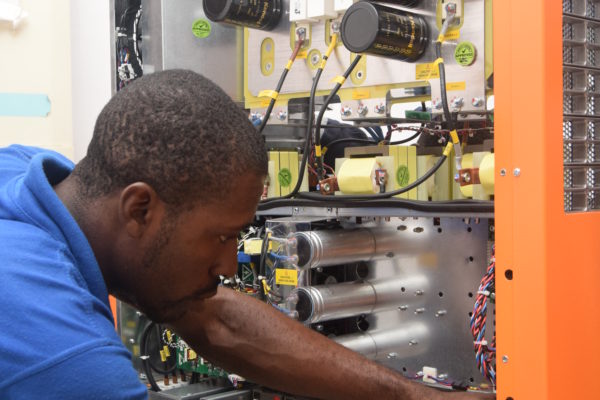

- Perform a preventative maintenance inspection on the batteries through an onsite visit. During the inspection, a technician can record the battery data as a way of performing periodic monitoring. This service inspection, as part of an ongoing preventative maintenance agreement, is the most common way to monitor batteries. Data that can be measured includes:

- Battery temperature –One of the most common reasons for UPS battery failure is incorrect temperature

- Individual impedance testing (ohmic value)

- Individual battery voltage

- Verify torque on each battery and thermal scan connection points to help identify failing components

- An additional way to monitor UPS batteries is to use a battery monitoring device that gathers data remotely and continuously. These devices vary in size and monitoring capability. Some examples of data that can be monitored are:

- Voltage changes over time

- Ambient temperature

- Float voltage

- Large power fluctuations

- Power anomalies

- Internal resistance values versus Ohmic baseline values

Most battery monitoring devices are meant to monitor single batteries in a string (at the “cell level”) so that potential issues are isolated before they cause catastrophic failures, such as thermal runaway.

Battery monitoring is used to essentially provide the same level of testing that a technician would perform, but on a continual basis. Most battery monitoring solutions will provide an intuitive dashboard that allows the user to view current battery health, as well as battery trends over time. This may provide the user with a better understanding of battery life cycles, as well as an added level of security in knowing you are alerted immediately in the event of an issue.

The end goal of any battery monitoring device is prevention of battery failure. Having regular preventative UPS inspections are an integral part of this process, but the addition of battery monitoring will provide a more thorough understanding of the overall UPS condition. Contact QPSif you have questions on the details of battery monitoring, and what type of monitoring device might work best for you.