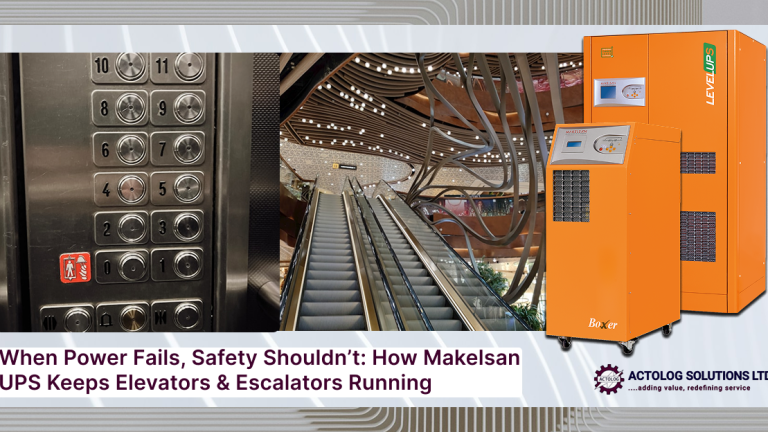

A technical look at how Actolog Solutions ensures uninterrupted vertical mobility through smart power protection design.

In today’s high-rise world — from shopping malls to corporate towers—elevators and escalators are not just conveniences; they’re critical lifelines. They transport people, enable accessibility, and keep business operations flowing.

But what happens when power fails?

A sudden outage can halt elevators mid-ride, trapping passengers, disrupting services, and creating serious safety risks.

In Nigeria’s reality of unstable grid supply and rising diesel costs, reliability is everything. That’s why Actolog Solutions Ltd, in partnership with Makelsan, is redefining how facilities approach backup power for elevators and escalators — through smarter, safer, and more resilient UPS (Uninterruptible Power Supply) systems.

The Challenge: Power Interruptions and Vertical Mobility Risks

Elevators and escalators depend on continuous, stable power for motors, drives, and control systems. When power supply is inconsistent, it creates a ripple of challenges:

- Passenger safety risks during entrapment or mid-ride stops

- Mechanical and control system damage from abrupt shutdowns

- Downtime and maintenance costs from frequent resets

- Loss of building credibility due to poor reliability

Traditional generators, while useful, don’t react instantly — it takes several seconds for them to start and stabilize voltage. Those few seconds can make all the difference between safety and chaos.

UPS: The Missing Link Between Safety and Continuity

A UPS (Uninterruptible Power Supply) bridges the gap between grid failure and generator startup. It delivers instantaneous backup power (0 ms transfer time), ensuring elevators and escalators continue operating smoothly even when the main supply drops.

For high-traffic buildings, hospitals, and commercial complexes, UPS systems are no longer optional — they’re a safety and compliance requirement.

Inside the Engineering: Challenges and Solutions

1. High Inrush Current and Load Fluctuations

Elevators, especially traction systems, require a high inrush current during startup—sometimes exceeding 400% of the running current. This causes large transient power surges that only well-designed UPS systems can handle.

Makelsan’s double-conversion UPS systems are engineered for such dynamic loads. Their power factor correction and overload tolerance ensure smooth operation during peak motor engagement.

2. Regenerative Drives and the Role of DBR (Dynamic Braking Resistors)

Modern elevator drives often regenerate energy during descent—feeding power back into the system. While this is efficient under normal grid conditions, during backup operation, it can back-feed into the UPS and cause faults.

To solve this, Dynamic Braking Resistors (DBRs) or load banks are integrated into the design. These components safely dissipate regenerative energy, protecting the UPS and maintaining system stability.

Actolog’s engineering team evaluates each installation to determine whether a DBR or load bank is required, ensuring total protection for both elevator drives and UPS components.

3. Runtime and Safety Compliance

Building standards increasingly require elevators to remain functional during outages—often for up to 90 minutes.

By combining Makelsan’s modular battery systems with optimized energy management, Actolog designs solutions that meet these run-time requirements without oversizing or compromising efficiency.

Our designs comply with international safety codes (e.g., IBC 3007/3008 standards for standby elevator power), providing building managers with peace of mind and assurance of compliance.

4. Seamless Generator Integration

While the UPS provides instantaneous backup, it can also sync perfectly with generators.

Actolog integrates ATS (Automatic Transfer Switches) and smart inverter controls to ensure that when the generator comes online, the transition is seamless—no flicker, no restart, no downtime.

5. Environmental and Maintenance Considerations

UPS and battery systems must operate reliably in Nigeria’s challenging environmental conditions — heat, humidity, and limited cooling.

Actolog accounts for these factors during design by:

- Using temperature-resilient lithium or AGM battery options

- Ensuring proper ventilation and fire-rated enclosures

- Implementing remote monitoring for temperature, voltage, and runtime

This proactive approach extends system lifespan and ensures consistent performance throughout the year.

Real-World Applications

Actolog’s elevator and escalator backup systems are ideal for:

- High-rise office and residential buildings

- Shopping malls and business complexes

- Hospitals and medical centers

- Hotels, airports, and industrial facilities

In each case, we customize the design based on load profile, building layout, and expected runtime—ensuring reliable power continuity for every ride.

Our Solution Framework

Here’s how Actolog Solutions approaches every project:

- Site Audit: Evaluate elevator load, drive type (regenerative or non-regenerative), and runtime requirements.

- System Design: Model the ideal Makelsan UPS configuration with proper battery and DBR sizing.

- Integration: Coordinate with elevator OEMs for compatibility and safety certifications.

- Installation: Deploy UPS, batteries, and load-management systems with minimal downtime.

- Monitoring & Maintenance: Provide SLA-based support, remote diagnostics, and periodic testing.

With this approach, building owners don’t just get equipment—they get a complete assurance of reliability and safety.

Case Example: Mid-Rise Commercial Tower in Lagos

A 12-floor commercial complex experienced frequent elevator shutdowns during short power dips. Actolog deployed a Makelsan 60 kVA three-phase UPS with external batteries for a 90-minute runtime.

A DBR module was added to handle regenerative energy, and an ATS system ensured seamless generator transfer.

Result: Zero downtime, improved tenant satisfaction, and full safety compliance—even during unplanned grid failures.

Why Choose Actolog + Makelsan

- Zero Transfer Time: Instant switchover ensures uninterrupted operation.

- Scalable Design: Modular UPS architecture grows with your building.

- Regenerative Ready: DBR integration keeps regenerative drives stable.

- Proven Reliability: Makelsan’s European-standard engineering meets Actolog’s local expertise.

- Full Lifecycle Support: From design to maintenance—one trusted partner.

Stay Powered. Stay Safe. Stay Connected.

When it comes to elevators and escalators, every second of uptime matters.

With Actolog Solutions and Makelsan, you’re not just powering motion—you’re powering confidence, safety, and continuity.

Because when power fails, safety shouldn’t.

🔗 Learn more about our Elevator & Escalator UPS Solutions

Visit www.actolog.com or contact info@actolog.com for a site assessment and customized design.